A look at synthetic biology and compact reactors for producing pharmaceuticals in situ.

A look at synthetic biology and compact reactors for producing pharmaceuticals in situ

When the first long-term Mars settlers arrive, they’ll face a pharmaceutical logistics nightmare. A simple infection, a broken bone, or chronic condition management on Earth becomes exponentially more complex when the nearest pharmacy is 225 million kilometers away and resupply missions arrive only once every two years. The solution isn’t stockpiling decades worth of medications, it’s building the capability to manufacture pharmaceuticals on Mars itself. Enter the concept of “radiation pharmacies”: compact, automated facilities that leverage Mars’s unique environment, synthetic biology, and advanced reactor technology to produce life-saving drugs on demand.

The Pharmaceutical Challenge of Mars

Before exploring solutions, it’s crucial to understand the scale of the problem. Pharmaceutical supply chains on Earth are marvels of modern logistics, but they’re entirely dependent on terrestrial infrastructure, abundant resources, and rapid transportation networks. Mars breaks every assumption these systems rely upon.

The Transit Problem: Even at optimal planetary alignment, cargo from Earth takes 6-9 months to reach Mars. Many pharmaceuticals have limited shelf lives, insulin, for instance, typically remains stable for only 2-3 years under refrigeration. Biologics, vaccines, and certain antibiotics degrade even faster. By the time a medication reaches Mars, its effective lifespan may be severely compromised.

Storage Constraints: Mass is precious on Mars missions. Launching one kilogram to Mars costs approximately $50,000-100,000 depending on the mission architecture. A comprehensive pharmacy for even a small crew of 50 people could weigh several tons. Multiply that by safety margins and redundancy requirements, and the mass budget becomes prohibitive.

Medical Uncertainty: You can predict general health needs, but you can’t foresee every medical emergency. A colonist might develop an unexpected allergic reaction requiring specialized antihistamines. Someone might need chemotherapy drugs for cancer. An outbreak of a resistant bacterial strain might demand antibiotics not in the standard formulary. Earth can’t respond fast enough to these scenarios.

Radiation Effects: Mars’s surface receives far more radiation than Earth—approximately 0.67 millisieverts per day compared to Earth’s background of about 0.007 millisieverts per day. This will increase cancer risk, potentially necessitating greater pharmaceutical intervention. Ironically, this same radiation environment creates opportunities for pharmaceutical production.

Compact Nuclear Reactors: Power and Isotopes

At the heart of Mars’s pharmaceutical independence lies advanced nuclear technology. Compact nuclear reactors serve dual purposes: providing reliable baseload power for energy-intensive pharmaceutical synthesis and producing medical isotopes essential for both diagnostics and treatment.

Radioisotope Production: Many critical medical procedures rely on radioactive isotopes. Technetium-99m, the workhorse of nuclear medicine, is used in over 40 million diagnostic procedures annually on Earth. It’s produced from Molybdenum-99, which decays with a half-life of only 66 hours, making it impossible to ship from Earth. A Mars medical facility would need to produce it locally.

Compact reactors designed for Mars could include specialized target assemblies where stable isotopes are bombarded with neutrons to create medical radioisotopes:

- Molybdenum-99/Technetium-99m: For diagnostic imaging

- Iodine-131: For thyroid treatments

- Cobalt-60: For sterilization of medical equipment and supplies

- Phosphorus-32: For treating certain blood disorders

- Strontium-89: For bone pain palliation in cancer patients

Kilopower and Beyond: NASA’s Kilopower project demonstrates the feasibility of compact fission reactors (10 kW to 10 MW) suitable for Mars deployment. These reactors use highly enriched uranium or alternative fuels, operate for 10-15 years without refueling, and could be modular—allowing multiple units to be deployed as a settlement grows.

For pharmaceutical production, reactors would need to be designed with accessible neutron flux zones where target materials can be irradiated. The engineering challenge involves balancing reactor safety, neutron economy, and accessibility for isotope harvesting without contaminating the primary power generation function.

Heat as Resource: Pharmaceutical synthesis often requires precise temperature control. Reactors produce significant waste heat that, with proper heat exchangers and thermal management systems, could drive chemical reactors, maintain fermentation vessels at optimal temperatures, and power distillation processes. On Mars, where every joule counts, this heat integration becomes economically essential.

Synthetic Biology: The Programmable Pharmacy

While nuclear reactors produce isotopes and power, synthetic biology represents the cutting edge of pharmaceutical production. By genetically engineering microorganisms to produce complex drug molecules, Mars settlements could operate biological “factories” that manufacture medications from basic feedstocks.

Engineered Microorganisms: Synthetic biology allows scientists to treat organisms like programmable machines. By inserting, deleting, or modifying genes, researchers can coax bacteria, yeast, or algae to produce pharmaceuticals that would otherwise require complex chemical synthesis or extraction from plants and animals.

On Mars, this approach offers extraordinary advantages:

- Compact Production: A tabletop bioreactor can produce thousands of doses of medication

- Feedstock Flexibility: Engineered organisms can utilize Martian resources—CO₂ from the atmosphere, water from ice, and minerals from regolith

- Programmable Output: Need a different drug? Upload new genetic instructions to reprogram your microorganisms

- Self-Replication: Organisms grow and reproduce, meaning you’re essentially producing your production capacity

Current Achievements and Mars Applications:

Several pharmaceuticals are already produced via synthetic biology on Earth, providing proof-of-concept for Mars applications:

Insulin: Since the 1980s, insulin has been produced by genetically modified E. coli and yeast. This represents a critical medication for diabetic colonists and demonstrates the maturity of the technology.

Artemisinin: This antimalarial drug, traditionally extracted from sweet wormwood plants, is now produced by engineered yeast. The process transforms simple sugars into complex drug molecules, a template for Mars pharmaceutical production.

Antibiotics: Various antibiotics including penicillin derivatives are produced through fermentation by modified microorganisms. Given the infection risks in a Mars habitat, local antibiotic production would be essential.

Vaccines: Hepatitis B vaccine, HPV vaccine, and others are produced using recombinant DNA technology. Mars settlements would need vaccination capabilities for both Earth diseases and potential novel Martian biological hazards (though unlikely).

CRISPR and Rapid Development: CRISPR gene editing technology enables rapid reprogramming of organisms. On Mars, this means a medical officer with appropriate training could potentially modify production organisms to create new medications in response to emerging needs. Imagine identifying a bacterial infection resistant to available antibiotics, sequencing the pathogen’s genome, identifying its vulnerabilities, and engineering organisms to produce a targeted antibiotic, all within weeks rather than waiting years for Earth to send the right medication.

Extremophile Advantages: Mars research could leverage extremophiles—organisms that thrive in harsh conditions. Certain bacteria tolerate high radiation, extreme cold, or low pressure. Engineering pharmaceutical-producing genes into radiation-resistant bacteria could create production systems that handle Mars’s environment better than Earth-evolved organisms, potentially even producing medications in partially shielded facilities rather than requiring full Earth-normal environments.

The Radiation Pharmacy Architecture

Integrating nuclear reactors, synthetic biology, and pharmaceutical chemistry into a functional Mars pharmacy requires careful systems architecture.

Integration and Automation: Given limited crew time and the need for reliability, the radiation pharmacy would be heavily automated. AI systems would monitor production processes, adjust parameters in real-time, flag quality control issues, and optimize production schedules based on predicted needs and available resources.

Feedstock: Making Drugs from Martian Resources

A truly sustainable Mars pharmacy must source raw materials locally. While some complex precursors might need to be imported from Earth initially, the goal is maximum self-sufficiency.

Carbon Sources: Mars’s atmosphere is 95% CO₂—an abundant carbon source. Using Fischer-Tropsch synthesis or biological fixation, this CO₂ can be converted into organic compounds that serve as feedstock for pharmaceutical synthesis. Engineered cyanobacteria or algae could capture CO₂ and sunlight (or artificial light powered by reactors) to produce sugars, which then feed pharmaceutical-producing microorganisms.

Nitrogen: Nitrogen is scarce on Mars (2.6% of atmospheric composition) but essential for many pharmaceuticals. Initial missions would need to import nitrogen or extract it painstakingly from the atmosphere. Long-term, closed-loop nitrogen recycling becomes critical, capturing nitrogen from waste products and reintroducing it into production systems.

Water: Mars has substantial water ice, particularly near the poles and in subsurface deposits. Water is essential for life, synthesis reactions, and as a solvent. Pharmaceutical-grade water requires extensive purification, but Mars’s ice provides the raw material.

Minerals and Trace Elements: Martian regolith contains various minerals including iron, magnesium, calcium, and sulfur compounds. Chemical processing can extract these elements for use in pharmaceutical synthesis. Some medications require trace metals (zinc, selenium, molybdenum) that would need to be either mined locally or carefully recycled.

Organic Synthesis Building Blocks: From basic inorganic materials, chemical synthesis can build up organic precursors. Methane, methanol, formaldehyde, acetylene, these simple organic compounds serve as building blocks for complex pharmaceutical molecules. While energy-intensive, Mars’s abundant solar energy (supplemented by nuclear power) could drive these syntheses.

Specific Drug Production Examples

To make this concrete, let’s examine how specific classes of pharmaceuticals might be produced on Mars:

Antibiotics (e.g., Penicillin, Tetracycline):

Insulin:

Painkillers (e.g., Morphine derivatives):

Radiation Countermeasures:

Vitamins and Supplements:

Cancer Therapeutics:

Quality Control and Safety

Producing pharmaceuticals is meaningless if you can’t ensure their safety and efficacy. Mars pharmacies would need rigorous quality control systems, potentially more stringent than Earth facilities given the high stakes of errors.

Analytical Equipment: High-performance liquid chromatography (HPLC), mass spectrometry, nuclear magnetic resonance (NMR) spectroscopy, and other analytical tools would be essential. These instruments verify drug identity, purity, and concentration. Miniaturized versions of these instruments exist and continue to improve, making them feasible for Mars deployment.

Sterility Testing: Pharmaceutical contamination could be catastrophic. Sterility testing using rapid microbial detection systems would be critical. Ironically, Mars’s low-microbial environment (likely sterile until humans arrive) creates advantages, fewer potential contaminants to worry about, though preventing Earth-origin contamination remains essential.

Stability Testing: Drugs must remain effective throughout their shelf life. Accelerated stability testing under various conditions helps predict longevity. Mars’s unique environment (lower pressure, different radiation levels, temperature cycling) might affect drug stability differently than on Earth, requiring local testing protocols.

Batch Release Criteria: Every production batch would need to meet stringent criteria before release: correct identity, appropriate purity (typically >95-99%), correct potency, absence of contaminants, proper sterility, and expected stability profile.

Regulatory Framework: Who approves pharmaceuticals produced on Mars? Earth-based regulatory agencies like the FDA or EMA? A Mars-specific authority? Early settlements will likely follow Earth regulations closely, but as Mars develops autonomy, local regulatory frameworks may evolve that balance safety with the unique constraints and needs of Martian medicine.

Challenges and Technical Hurdles

While the vision of Mars pharmaceutical independence is compelling, significant challenges remain:

Complexity and Reliability: Pharmaceutical production involves complex, multi-step processes where contamination or parameter variations can ruin batches. Creating systems reliable enough to operate with minimal human intervention in Mars’s harsh environment represents a substantial engineering challenge.

Intellectual Property: Many pharmaceuticals are protected by patents. Would pharmaceutical companies license production technologies to Mars settlements? Would Mars settlers produce medications regardless of Earth patent law? These legal questions remain unresolved.

Waste Management: Pharmaceutical production generates chemical waste, spent biological materials, and contaminated equipment. Mars has no natural environment to absorb this waste. Closed-loop systems that recycle materials and neutralize hazardous waste are essential but technically demanding.

Energy Requirements: While Mars has abundant solar energy (despite being farther from the Sun), pharmaceutical production is energy-intensive. Balancing power demands between life support, pharmaceutical production, and other needs requires careful planning.

Human Expertise: Operating a pharmaceutical facility requires expertise in chemistry, microbiology, engineering, and medicine. Early Mars crews will be generalists. Training colonists in pharmaceutical production or developing AI systems capable of managing production with minimal human oversight represents a key challenge.

Mutation and Drift: Production organisms can mutate or evolve, potentially reducing productivity or producing unwanted byproducts. Regular monitoring and periodic refreshing of production strains from frozen stocks would be necessary.

Supply Chain Vulnerabilities: Even with local production, some materials, specialized reagents, or replacement parts might need to come from Earth. Identifying these critical dependencies and building redundancy is essential.

Beyond Medicine: Dual-Use Technologies

The infrastructure for pharmaceutical production has broader applications:

Industrial Chemistry: The same synthetic biology platforms and chemical reactors can produce industrial chemicals, plastics, lubricants, and other materials needed for manufacturing and construction.

Agriculture: Genetically modified organisms producing pharmaceuticals share technology with organisms producing agricultural products, vitamins for food supplementation, or even food itself (cellular agriculture).

Research Capabilities: The analytical equipment and expertise required for pharmaceutical production enables broader scientific research into Martian biology (if any exists), geology, atmospheric chemistry, and materials science.

Biotechnology Export: If Mars develops unique pharmaceutical production techniques or discovers novel compounds, these could potentially be exported back to Earth, creating an economic basis for the settlement.

Ethical and Societal Considerations

Pharmaceutical production on Mars raises interesting ethical questions:

Allocation and Rationing: If production capacity is limited, how are medications allocated? Earth operates under various models (market-based, single-payer, mixed systems). Mars might develop its own approaches based on collective survival needs.

Experimental Treatments: With limited regulatory oversight and desperate circumstances, would Mars settlers be more willing to try experimental or off-label treatments? This could accelerate medical innovation but also risks tragedy.

Genetic Engineering Governance: The power to engineer organisms to produce desired compounds is also the power to create harmful organisms. How does a Mars settlement prevent misuse while enabling beneficial innovation?

Pharmaceutical Knowledge as Commons: Should pharmaceutical production knowledge on Mars be open-source, shared freely to ensure survival? Or would proprietary knowledge drive innovation?

Enhancement vs. Treatment: In Mars’s challenging environment, the line between treating disease and enhancing human capabilities may blur. Should Mars pharmacies produce performance-enhancing drugs to help colonists cope with their environment?

Conclusion: Prescription for Success

The development of radiation pharmacies and on-site pharmaceutical production represents one of the most critical technologies for long-term Mars habitation. It’s not optional—it’s essential for survival, health maintenance, and true independence from Earth.

The convergence of compact nuclear reactors, synthetic biology, automated chemistry, and advanced manufacturing creates unprecedented opportunities. For the first time in history, a small population far from Earth could maintain comprehensive pharmaceutical capabilities comparable to what Earth hospitals provide.

This isn’t just about making medicine on Mars, it’s about reimagining pharmaceutical production from first principles. The constraints of Mars force innovation: extreme efficiency, resource recycling, multi-functionality, and automation. These innovations could flow back to Earth, providing models for pharmaceutical production that’s more sustainable, more accessible, and more adaptable.

The Mars settler experiencing a bacterial infection and taking an antibiotic produced last week in a local bioreactor, powered by a compact nuclear reactor, formulated from Martian atmospheric CO₂ and subsurface ice, represents a profound achievement: human self-sufficiency on another world.

As we plan humanity’s expansion into the solar system, radiation pharmacies exemplify the type of thinking required, not just transporting Earth’s solutions to new worlds, but developing new solutions appropriate to new circumstances. The red planet may seem barren and hostile, but with the right technology, it can become a place where humans not only survive but thrive, their health maintained by pharmacies that turn Martian rock, air, and atoms into life-saving medications.

The prescription for Mars’s success includes more than food, water, and shelter. It requires the ability to heal, to maintain health, and to respond to medical challenges with the full arsenal of pharmaceutical science, produced not millions of kilometers away, but right there on Mars, synthesized from the very planet that settlers now call home.

What pharmaceutical production technologies do you think are most critical for Mars missions? Share your thoughts in the comments below.

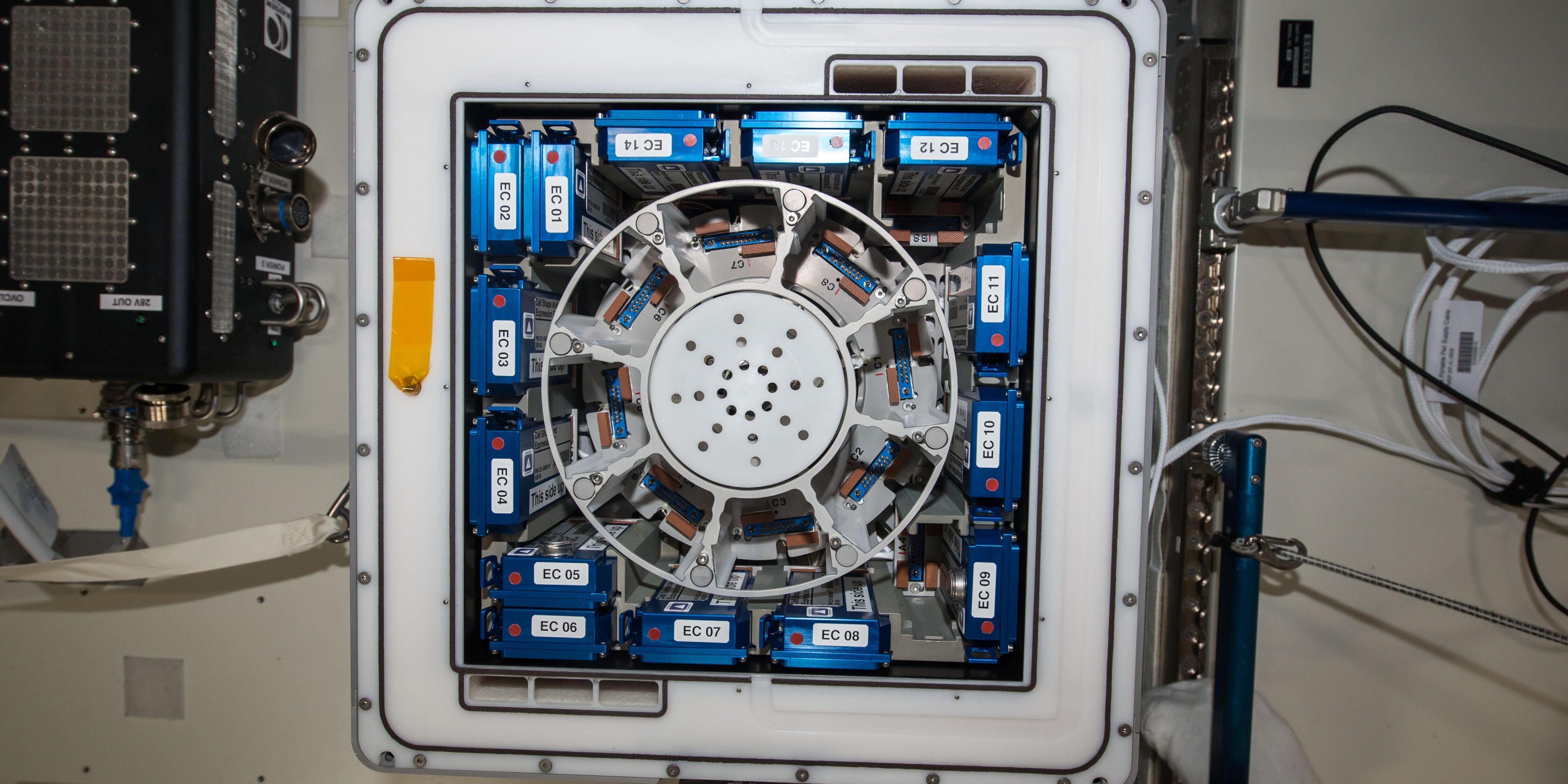

@ImageCredits ESA Kubik